Welcome, dear visitor,

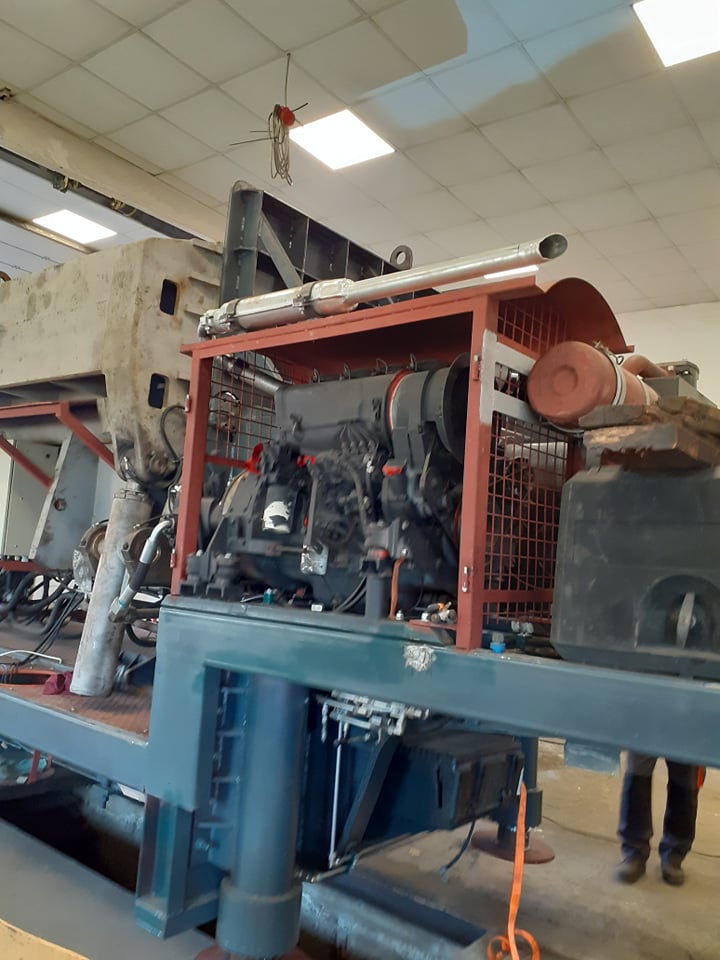

I’m a Lefort GA 700 scrap metal shear/baler machine.

Unfortunately, at my previous workplace, little attention was paid to my maintenance, so my condition was quite deteriorated. I got to the site of Zöld-Gépezet Co. Ltd., when my previous employer bought another machine and I was included in the price of it.

Then I was extremely desperate because I thought I would never work again. However, thanks to the experts of Zöld-Gépezet Co. Ltd.., I am again like when I was young, and even more productive!

I have 300 tons of cutting power, and my tray is 3.6 meters long. My original engine was a 6-cylinder Deutz engine, which was replaced by Zöld-Gépezet Co. Ltd. with a 4-cylinder, air-cooled Deutz engine. So I not only do my work more efficiently, but also my consumption remained unchanged.

Without the professionals, I probably should have retired by now, but now I can work again with the same dynamism and effort as when I fell off the production line. Of course, a lot of work was done on me to do that.

Among other things:

- The Shear’ head was put in order

- Blades and sliding elements have been replaced

- Improvement of the guillotine is done

- Repair of the working cylinder

- Reline the box

- The bushings have been replaced

- The 4-cylinder Deutz engine has been subjected to general overhaul

- The pump has been renovated

- New control electronics has been installed

- The sandblasting and painting is done

- In addition a new security door has been manufactured

And I haven’t even mentioned the best one yet.

I am originally a stable machine designed to work in one place, but the employees of Zöld-Gépezet Co. Ltd.. bought me a 3-axis Trailor trailer. I was built into this and even passed a road test, so instead of boring standing still, I can now do the job I do best: scrap metal processing, which is the greatest pleasure for me!